State of the art technology

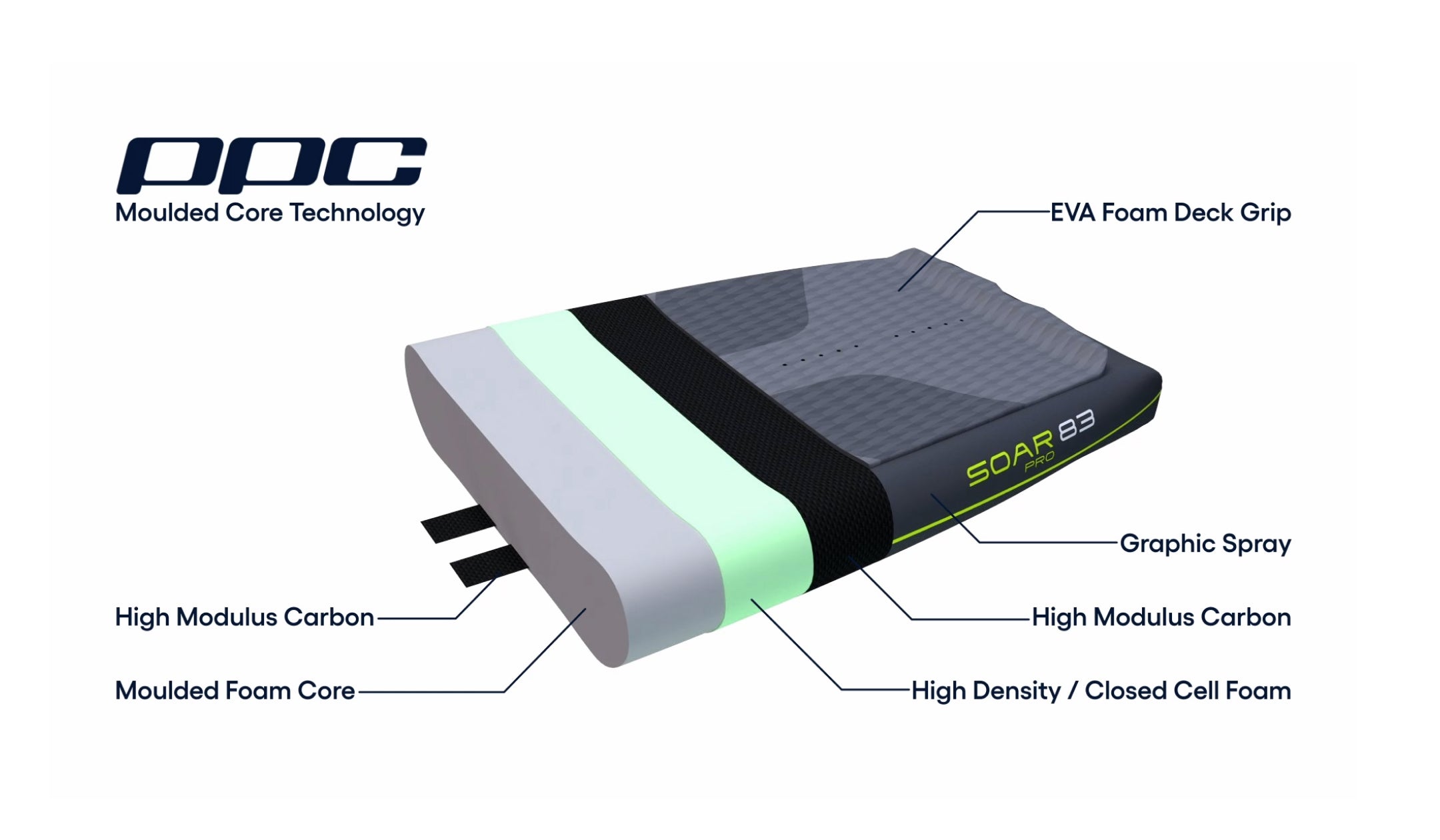

Discover the unparalleled strength and performance of our PPC foil boards, meticulously crafted with Moulded Core Technology (MCT) construction. Designed to withstand the rigorous demands of foiling, your board serves as your ultimate connection to the water, making it a pivotal component of your gear arsenal.

With MCT construction at the core, our PPC boards offer unmatched durability and stiffness, whilst being extremely light, setting them apart as leaders in the industry. But our commitment to excellence doesn't stop there. Behind every PPC board lies a carefully guarded formula, a proprietary blend of materials and meticulous lay-up techniques that elevate our boards to a league of their own.

Experience the difference with PPC foil boards – where innovation meets passion, and performance knows no bounds.

Performance

Unleash your full potential on the water with MCT Construction. Engineered to perfection, our boards boast exceptional stiffness, facilitating an efficient transfer of energy from rider to foil. Feel the responsiveness and control as you carve through the waves with unparalleled precision and power.

Strong and durable yet lightweight

Strength meets agility in our MCT Construction boards. Crafted with a smoother core and a concrete-like shell, our build process ensures unmatched durability and longevity. Despite their robust construction, our boards remain remarkably lightweight, allowing for swift manoeuvres and reduced swing weight. Get out of the water faster and dominate every session with confidence.

Sustainability

Join us in our commitment to a greener future with PPC MCT Boards. By embracing innovative construction techniques, we minimise foam and resin wastage, setting a new standard for sustainability in the industry. Our boards are not only eco-friendly but also built to last, reducing the need for frequent replacements and further reducing environmental impact.

The M1 is the best wing I've used and I've got pretty much every wing on the market.

Light, durable, efficient, the PPC Soar Pro does not disappoint!

The PPC M1 wing is my new favorite. This thing solidly handles any gusts, and has almost no flutter.

Soar Pro Foil Board

Description

The Soar Pro. A model derived from the current popular Soar model. A flattened deck, narrower width board with the same sharp lines as the Soar, the Soar Pro ensures the advanced rider gets the most out of their wing foiling sessions!

The increased water line ensures early take off, while the narrow width gives that direct feel over the foil in hard carves & general wing foiling maneuvers.

Built from the same unique super stiff moulded core / multi layer uni-directional carbon construction as all our boards, the Soar Pro will hold up to the abuse an advanced rider will put them through!

Insert stance gap has been widened for race use. The smaller sizes work incredibly as prone foil boards. Available in 5 sizes from 4’3 (43L) through to 5’2 (83L).

If you require a tuttle box option, please order through your local dealer.

| Sizes | Volume | Weight |

| 4’3 x 21 | 43L | 3.85Kg |

| 4’5” x 22.5 | 53L | 4.25Kg |

| 4’8 x 23 | 63L | 4.65Kg |

| 4’11” x 23.5 | 73L | 5.1Kg |

| 5’2” x 23.9 | 83L | 5.45Kg |

| 5’4” x 24.2 | 93L |